Standard channel letters are widely used in modern signage for their durability, professional appearance, and excellent illumination. The manufacturing process is precise and involves several key components to ensure high quality and longevity. Here’s a detailed overview of how standard channel letters are typically constructed.

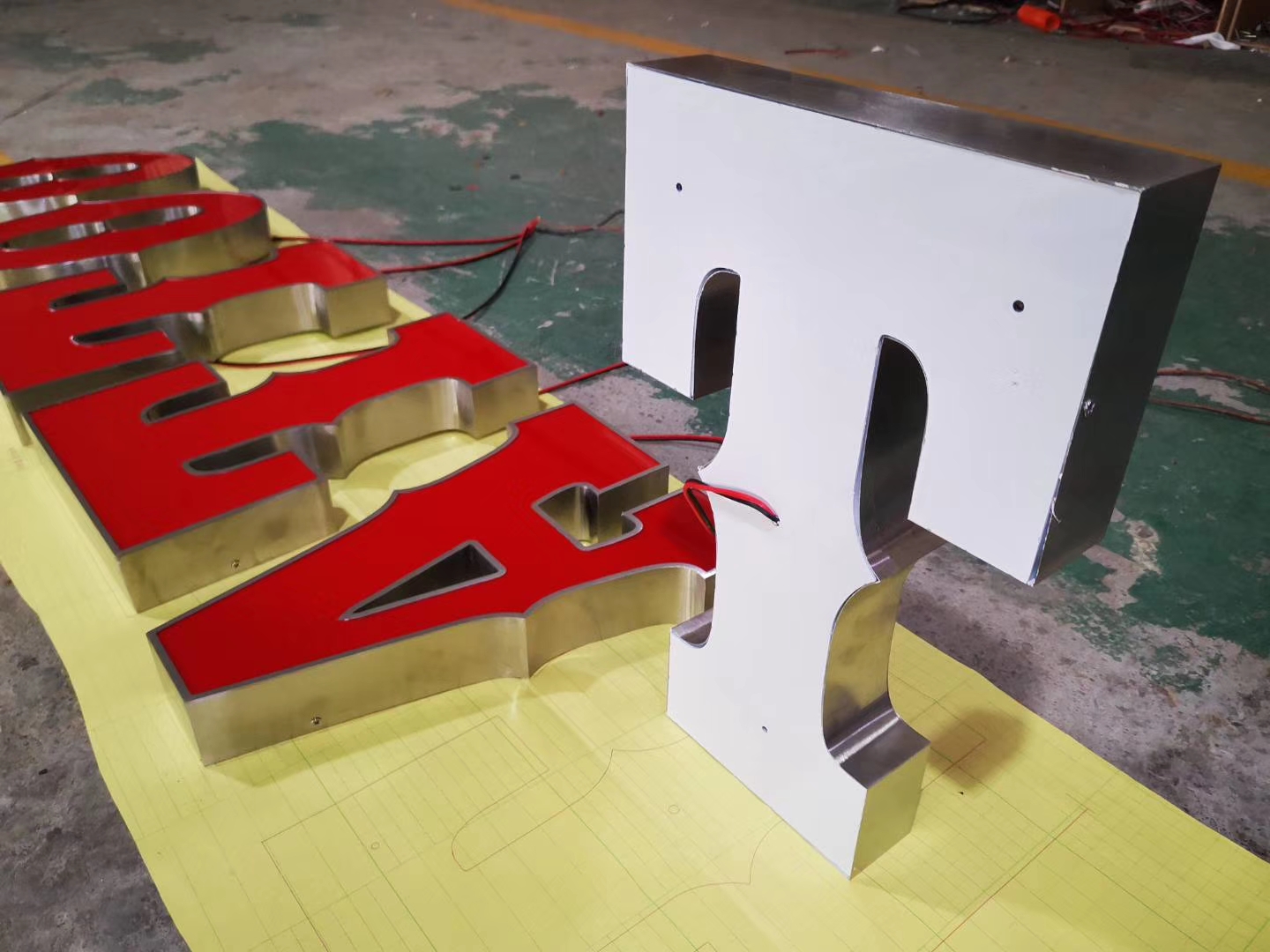

Each channel letter begins with the fabrication of the sides, also known as the “returns.” These are usually made from stainless steel or aluminum due to their strength and resistance to weathering. The returns are carefully bent and welded into the desired letter shape, forming a shallow, three-dimensional channel.

A critical feature of the design is the 3–10mm trim (or lip) along the front edge of the returns. This lip is engineered to hold the face material securely in place. The most common material for the face is 3mm or 5mm thick milky white acrylic. This type of acrylic is preferred because it diffuses light evenly, eliminating hot spots and ensuring a consistent, professional glow when the sign is illuminated. The acrylic sheet is carefully cut to shape and then snapped into the trim, creating a tight and seamless fit.

The back of the letter is sealed with a 10mm PVC backplate. This panel serves multiple purposes: it protects the internal components from dust and moisture, provides a rigid mounting surface, and acts as a background that enhances the visibility of the letter during the day. Mounting holes are pre-drilled into the PVC to facilitate installation on various surfaces.

The lighting is provided by high-quality LED modules. These energy-efficient and long-lasting lights are installed directly onto the PVC backplate. Their placement is strategically planned to provide uniform brightness across the entire letter. Finally, the backplate is securely attached to the metal returns using flat-head screws fastened from the side. This method creates a clean, finished look without any visible screw heads on the front of the sign.

This combination of a welded metal return, a clipped acrylic face, and a screw-fastened PVC backplate results in a robust, reliable, and visually appealing signage solution perfect for a wide range of business applications.

Keywords: channel letters, sign manufacturing, LED channel letters, acrylic sign face, stainless steel returns, PVC backplate, commercial signage, custom signs, illuminated signs, sign fabrication.