What is ACP Material?

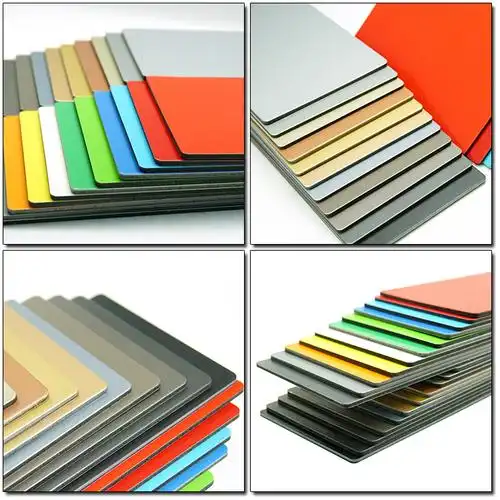

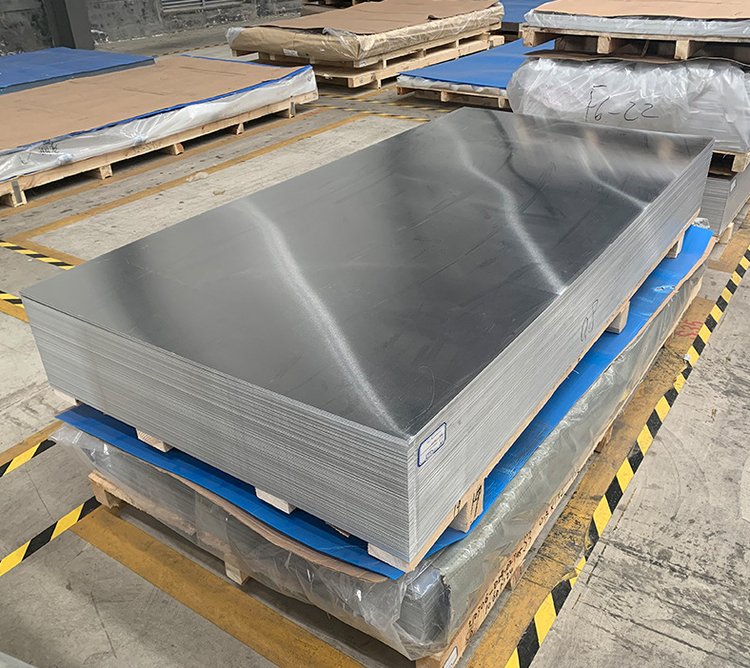

ACP stands for Aluminum Composite Material (often called ACM in North America). It is a flat panel made from two thin, coil-coated aluminum sheets bonded to a non-aluminum core, typically made from polyethylene (PE) or a fire-retardant mineral core.

Think of it as an “aluminum sandwich.” The outer layers provide a durable, paintable, and weather-resistant surface, while the inner core provides rigidity, strength, and lightness.

Why is ACP So Popular in the Sign Industry?

ACP has become one of the most dominant materials for modern signage due to its unique combination of properties:

1. Lightweight yet Rigid:

Compared to solid aluminum or steel, ACP is incredibly light. This makes fabrication, handling, and installation much easier and safer. It reduces the load on building structures and allows for larger sign sizes without excessive weight.

2. Excellent Fabricability:

ACP is easy to work with using standard woodworking and metalworking tools. Sign shops can easily:

-

Cut it with CNC routers, panel saws, or even jigsaws.

-

Bend it (using a “brake”) to create folded faces, returns, and 3D structures.

-

Drill and machine it to create holes for mounting or special effects.

-

Route it to create channels for LED lights (see “Lightboxes” below).

3. Superior Surface Finish:

The aluminum sheets are coated (often with PVDF resin like Kynar 500® or Hylar 5000®) in a vast array of colors, metallics, and textures.

-

Consistency: The color and finish are perfectly uniform, unlike painted surfaces which can have variations.

-

Durability: The coating is highly resistant to fading, chipping, and weathering, ensuring the sign looks new for years.

-

Options: Available in glossy, matte, metallic, brushed, and even woodgrain or stone patterns.

4. Flatness and Stability:

ACP panels remain exceptionally flat and do not warp or buckle easily. This is critical for creating large, seamless sign faces that look professional and high-end.

5. Cost-Effective:

It offers the premium look of solid metal at a fraction of the cost, both in material and the labor required to fabricate it.

Common Applications of ACP in Signage

ACP is incredibly versatile. Its primary uses include:

-

Dimensional Letters & Logos: This is one of the most common uses. The panels are cut to shape on a CNC router, and the returns (sides) are often formed from the same material for a clean, seamless look.

-

Fascia Signs & Building Signage: Large, flat sign faces mounted directly to a building’s wall or parapet. ACP provides a smooth, modern canvas for company logos and graphics.

-

Lightboxes: The panels are routed to create a “lip” or “rabbet” that holds the acrylic face, allowing for the integration of LED modules to create illuminated signs.

-

Directory Signs & Wayfinding: Used for interior and exterior informational signs due to its clean appearance and durability.

-

Architectural Accents: Often used for elements like column covers and soffits that are part of a branded environment.

Key Considerations When Using ACP for Signs

1. Core Type:

-

Polyethylene (PE) Core: The standard, most economical option. Suitable for most interior and many exterior signs. However, it is combustible and is often banned or restricted for use above a certain height on buildings due to fire safety codes (especially after incidents like the Grenfell Tower fire).

-

Fire-Retardant (FR) Core: Filled with mineral compounds (not plastic). It is non-combustible or has a very limited combustibility. This is the required material for most commercial and high-rise building applications. Always check local building codes.

2. Thickness:

The most common thicknesses are 3mm (ideal for most interior signs and smaller letters) and 4mm (the standard for exterior building signs and larger letters). Thicker options (6mm) exist for applications requiring extra rigidity.

3. Mounting and Fabrication:

-

For flat sign faces, a substructure (often aluminum tubing) is used to mount the panel.

-

For letters, a combination of adhesive and mechanical fasteners is used to attach the returns to the face.

-

Proper sealing of cut edges is crucial for exterior applications to prevent moisture from entering the core.

ACP vs. Common Alternatives

| Material | Pros | Cons | Best For |

|---|---|---|---|

| ACP (Aluminum Composite) | Lightweight, rigid, flat, durable finish, cost-effective, easy to fabricate. | Can dent if struck; PE core is flammable if not specified as FR. | The go-to for most modern commercial signage: dimensional letters, lightboxes, fascia signs. |

| Solid Aluminum | Very strong, durable, can be welded, non-combustible. | Heavy, more expensive, requires more labor to fabricate. | Heavy-duty industrial signs, high-wear applications, where welding is needed. |

| Acrylic (Plexiglas) | Excellent for illumination, high-gloss finish, can be thermoformed. | Can be brittle and crack, scratches more easily, not as rigid for large spans. | Illuminated channel letters, full-face lit signs, decorative elements. |

| PVC/Foam Board | Very lightweight, cheap, easy to cut. | Not durable, warps in sun/heat, looks cheap, not for long-term use. | Short-term indoor signs, trade show graphics, temporary displays. |

Conclusion

In summary, ACP is the workhorse material of the modern sign industry. Its perfect blend of lightness, strength, fabricability, and aesthetic quality has made it the default choice for creating professional, durable, and cost-effective signs for businesses worldwide. When specifying it, always prioritize the correct fire-retardant core for architectural applications to ensure safety and compliance.