Today, 3D printing technology has been widely used in various fields, but its advantages and disadvantages are very obvious. For 3D printing may replace the traditional molding technology. At least in a short time, is unlikely to be achieved.

In the face of the complex structure, 3D printing has obvious advantages. As all manufacturing processes are pre-configured through the computer. As long as the settings are correct, 3D printers will seriously complete its work well. Due to the need for frequent manual operation, the error is inevitable to the traditional molding technology.

For example, to produce a mold, it may need to go through the election material, cutting, polishing, stamping and a series of processes. And in these processes as long as there is a little mistake, the material will be wasted. Then you need to start all over again. The use of 3D printing, as long as we choose the material, set the drawings, press the Start button, then you can go to have a cup of coffee.

Compared with the traditional molding technology, 3D printing is also very obvious shortcomings. The most obvious shortcoming is not anti-fall. 3D printing is currently more commonly used in polymer materials. And each material has its own melting point and fluid and other properties. 3D printing is difficult to achieve with the current variety of materials, resulting in printed products brittleness and other shortcomings.

In view of above analysis, 3D printing completely replace the traditional molding technology, can not be achieved at this stage. However, if put these two technologies together, I believe that at this stage can also produce wonderful chemical reactions.

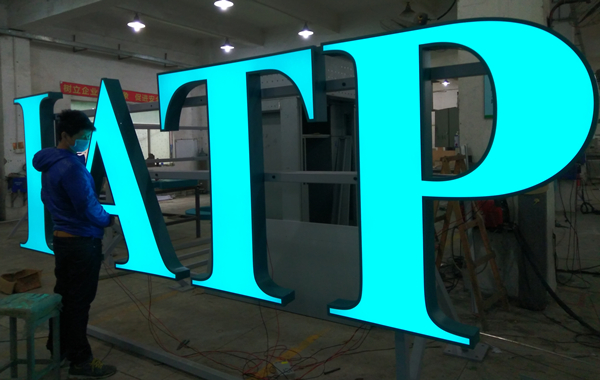

For more information, please check www.acpsigns.com (Top Signs Manufacturers in China). If you need any Lettering Signs, Lighting Boxes, Pylon Signs, or any other Signs, let’s talk about it together.